WE ARE

QUICKBLOCK

ANYTHING. ANYWHERE.

We are a Scotland-based start-up with an ambitious team dedicated to sustainability and safety.

Our passion drives us to create bespoke QUICKBLOCK solutions for customers worldwide, addressing diverse challenges and partnering with trade and retail organisations to make our product widely available.

VISION

We aim to empower individuals everywhere to build with QUICKBLOCK. Our mission is to offer a sustainable building solution that reduces waste and supports a circular economy.

We aim to provide rapid-build infrastructure that can be deployed globally to ensure safety in humanitarian disasters and conflict zones.

Join us on our journey to create a greener future for all.

OUR

HISTORY

ISE INNOVATION AWARD

SEPTEMBER 2024

QUICKBLOCK Defence was chosen as the 2024 innovation winner at the International Security Expo. This is fantastic recognition for the hard word, development and innovation that goes on behind the scenes.

THE QUICKBLOCK SHELTER

AUGUST 2024

Our Product Manager Marc and CEO Andrew were delighted to launch The QUICKBLOCK Shelter in Camp Roberts, California US.

This prototype structure has been in development for some time

and a fantastic milestone for the QUICKBLOCK team.

FIRST QUICKBLOCK SHELTER PROTOTYPE

JUNE 2024

First full manufactured prototype of QUICKBLOCK Shelter System is built in Stirling Office.

TEAM GROWTH

JUNE 2024

Increased the team to 9 employees including 2 BusinessDevelopment Managers, a Marketing Manager and 2 Interns.

QUICKBLOCK SHELTER WINDOWS & DOORS

JUNE 2024

First manufactured prototypes of QB Shelter window and door are created.

SCALE UP PROGRAMME

MAY 2024

We are delighted to be part of the Sir Tom Hunter Scale Up Programme which our CEO attends once a month.

3RD INVESTMENT ROUND

JAN 2024

£1.3m investment round at the beginning of 2024 (Equity Gap, University of Strathclyde, Scottish Enterprise and DASA Defence Innovation Loan). At this stage we welcomed Kim McLaren, Head of Operations to the team.

MOVED TO UK MANUFACTURE

JANUARY 2024

QUICKBLOCK moved manufacturing the blocks from China to the UK(Yorkshire) in 2024 to become a more sustainable organisation and to reduce any issues with shipping the product to the UK. First QUICKBLOCK V2 Blocks come off the manufacturing line at Protomould/Plastech.

QUICKBLOCK DEFENCE INFRASTRUCTURE

DECEMBER 2023

Troop trial of QUICKBLOCK subterranean command cell take place in Bovington.

QUICKBLOCK BALLISTIC TESTING

OCTOBER 2023

Ballistic tests on plastic block with sand infill conducted.

DTECH AWARDS FINAL 7

JULY 2023

We entered the DTECH awards and made the final 7 in Singapore.

FIRST QUICKBLOCK V2 & HVM TRIALS

JUNE 2023

The first injection moulded V2 blocks from the tool at Protomould are delivered. This same month the second HVM trials take place with rubber block infill.

PROOF OF CONCEPT - QUICKBLOCK SHELTER

JANUARY 2023

Proof-of-concept QUICKBLOCK Shelter roof prototype built in our Stirling office.

FIRST PROTOTYPE OF RUBBER BLOCK

OCTOBER 2022

The creation of the first Prototype of QUICKBLOCK Rubber Block manufactured for HVM Planters.

MSIP ELEVATOR PROGRAMME

AUGUST 2022

We were delighted to have been selected to be part of theMichelin Scotland Innovation Parc (MSIP) Elevator Programme and the Unlocking Ambition programme.

QUICKBLOCK V2

JUNE 2022

The first injection moulded V2 blocks from the tool at Protomould are delivered. This same month the secondHVM trials take place with rubber block infill.

2ND INVESTMENT ROUND

MAY 2022

£350,000 investment round from Equity Gap, Scottish Enterprise

and Strathclyde University.

QUICKBLOCK FOR HVM

MARCH 2022

First trials for HVM (Hostile Vehicle Mitigation) look place in the form of planters.

QUICKBLOCK DEFENCE TESTING

FEBRUARY 2022

Blast trials of the Defence block and plastic block with infill take place.

NEW OFFICE IN STIRLING

JANUARY 2022

For a more central location, the small QUICKBLOCK team moved to Stirling in Springfield Industrial Estate.

FIRST OFFICE LOCATION

AUGUST 2021

QUICKBLOCK’s first ever office and headquarters was opened in Glasgow.

FIRST DASA CONTRACT WON

JUNE 2021

A second DASA (MoD) contract was awarded to QUICKBLOCK for

£238,000 to go beyond the proof of concept and test in a blast

and ballistic setting for both the original QUICKBLOCK but also

QUICKBLOCK Defence block.

FIRST EMPLOYEE HIRED

JUNE 2021

Apart from Andrew (CEO) the first employee was hired was Marc Britovsek, the current Product Manager.

SCOTTISH EDGE WINNERS

JUNE 2021

Scottish Edge Circular Economy Award Winner in 2021 – £80,000

SEED ROUND INVESTMENT

APRIL 2021

£250,000 seed investment (Equity Gap and Scottish Enterprise) to build the team and take the product to market.

QUICKBLOCK DEFENCE

FEBRUARY 2021

Full-scale prototype of the Defence block manufactured – user trials take place and ballistic testing takes place.

LARGE SCALE PRODUCTION

JUNE 2020

The initial foundations were being put in place to start large scale production of QUICKBLOCK.

FIRST DASA CONTRACT

JANUARY 2020

£120,000 DASA Take Over! contract awarded to develop the concept of using the blocks for blast and ballistic protection and developing a concept for an armoured block.

QUICKBLOCK V1

JUNE 2021

Minimum viable product launched for commercial markets.

ANDREW JOINS AS CEO

SEPTEMBER 2019

Andrew’s initial job was to adapt the original blocks to use plastic waste instead of metal. He then highlighted a new strategic vision aimed at advancing the company’s growth through focus on the Defence, Security and Humanitarian sectors.

CONCEPT, REALITY & PROTOTYPES

2013 – 2019

During this development phase there were many people involved in developing the QUICKBLOCK concept and making it become a reality with the creation of prototypes and conducting market research.

QUICKBLOCK IDEA BORN

2013

The original QUICKBLOCK concept (called FastForm) was developed in the Middle East back in 2013. Faced with a significant waste problem, a small group of Scottish inventors envisioned the idea of repurposing this waste (aluminium at this stage) in a practical way to provide rapidly deployed shelters/temporary accommodation.

OUR VALUES

Be Brave and Innovate

Always try new things, engineer better ways and not be afraid to challenge the status quo.

Love the Planet

Everything we do should consider the planet and the communities around us.

Be the team-mate you want to have

Act with integrity, understanding, be open to new ideas and always be honest.

Love What You Do

We deliver with a smile on our face and a passion for what we do. Always deliver quality.

Never Give Up

We’re resilient, solve problems and are in this for the long haul.

meet the team

ANDREW VINCENT

CEO

JOHN DORNAN

HEAD OF BUSINESS DEVELOPMENT

KIM McLAREN

HEAD OF OPERATIONS

MARC BRITOVSEK

PRODUCT MANAGER

JENNIFER TERVIT

MARKETING MANAGER

BRYAN ANDERSON

BUSINESS DEVELOPMENT MANAGER

RYAN RITCHIE

BUSINESS DEVELOPMENT MANAGER

NICOLE DOYLE

MARKETING ASSISTANT

EWAN POWER

PRODUCT ASSISTANT

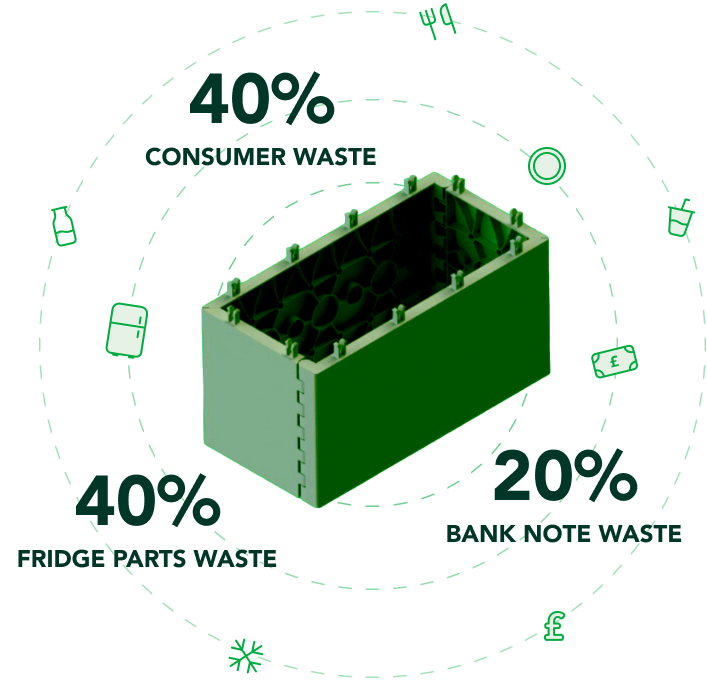

CIRCULARITY

Our blocks are incredibly easy to use and can significantly lower your project’s carbon footprint. Made from 100% recycled materials from a range of sources as shown in the diagrams below.

Available in two colours, grey and green, QUICKBLOCK offers a versatile and eco-conscious building solution. For custom colours, please get in touch as we would be delighted to help.

As an organisation that is focused on providing sustainable solutions, we were keen to find a business that would be able to provide an alternative building material that is also sustainable.

The team at QUICKBLOCK delivered as promised and we are absolutely thrilled with the product.

Woodlands Renewables

The blocks are a game changer for us, work that would have taken a couple of days has taken us an afternoon, they’re so easy to use that the guys really enjoyed building with them.

We’re already looking at other projects we can use these blocks for!

David Graham, Underbelly Edinburgh

HAVE SOME

QUESTIONS?

Depending on your requirements, QUICKBLOCK can be purchased by the pallet from one of our distribution partners such as B&Q, alternatively, if you have a custom project simply contact our sales team who will be happy to assist you with your plans.

The QUICKBLOCK building system comprises full blocks, half blocks, quarter blocks and capping pieces, every project is unique and therefore requires different quantities of the elements of the system to complete each project, to get an accurate quote for your project please contact our sales team.

The QUICKBLOCK system can be adapted to accommodate most roofing structures, contact our sales team who will be able to guide and advise on the best option for your specific project.

Our standard blocks are not flame retardant and are classed as an ordinary combustible just like wood and fabric however we can add a flame-retardant agent during the manufacturing process at the customers request, If you require your QUICKBLOCK to be flame retardant please speak with our sale team who will be happy to assist you.

Whether you need to infill the blocks with material such as sand or aggregate will depend on the structure you’re building, we also offer rubber block inserts and structural fixing plates our blocks can be modified to meet most requirements so speak with one of the team who will be able to advise on the best solution for you.

Concrete bricks are smaller, so you need more of them, they also require sand, cement, skilled trades people to build it for you and expensive concrete footings not to mention that when it comes time to rip it out, it’s expensive to dispose of concrete. QUICKBLOCK offers a cost-effective solution for people who want to build structures quickly and easily and who may wish to reconfigure or move the structure at a later date.

Currently we offer Olive green and grey as our standard colours, we can offer custom colours at the customer’s request which carry minimum order quantities and slightly more cost per block.

We aim to have orders delivered within 3 working days; this may be slightly longer during busy periods but we will always advise at the time of ordering with us.

At QUICKBLOCK durability is something we take very seriously that’s why we’ve taken steps to ensure our product doesn’t go brittle in the sun. During the manufacturing process we combine a UV stabilising agent with our recycled polypropylene ensuring a long lasting product even in harsh sunlight.

QUICKBLOCK is specially designed to be a temporary construction material that’s ideal for being reused and reconfigured as required and is ideal for building all kinds of temporary to semi-permanent infrastructure from garden planters to workshops and even temporary living spaces. Unfortunately QUICKBLOCK is not certified for permanent dwellings but this is something that may be possible in the future.